ZyNthAir

Accurate, Easy and Reliable Combustion for PAC Cetane analyzer

Accurate, Easy, and Reliable Combustion Air

The PAC ZyNthAir Gas Mixer is an accessory for existing CID510 Cetane Analyzer that removes the need for synthetic air while producing constant, reliable and accurate combustion air. The ZyNthAir is backward compatible with existing CID510 users as well as new users, and many of them will benefit from the reduced cost of purchasing synthetic air and the need to perform a Cetane calibration between gas cylinder swaps.

ZyNthAir requires three gas inputs: Nitrogen and Zero Air used to synthesize the 20% Oxygen for reliable combustion, and then small amounts of Oxygen for the automatic calibration of the Oxygen Sensor. The system mixes this gas to produce accurate combustion air with oxygen content of 20%+/- 0.05%.

Take the performance of your Cetane measurement to the next level

The CID 510 by PAC is proven to be the most precise analyzer for cetane measurement. It uses a patented method, ASTM D7688, and is included in fuel specifications while providing perfect correlation to ASTM D613. With the CID510 for a typical refinery of 100,000 bpd we can run 0.5 Cetane numbers closer to spec than with a tradition engine method, which means savings of up to $400K per year on cetane improvers.

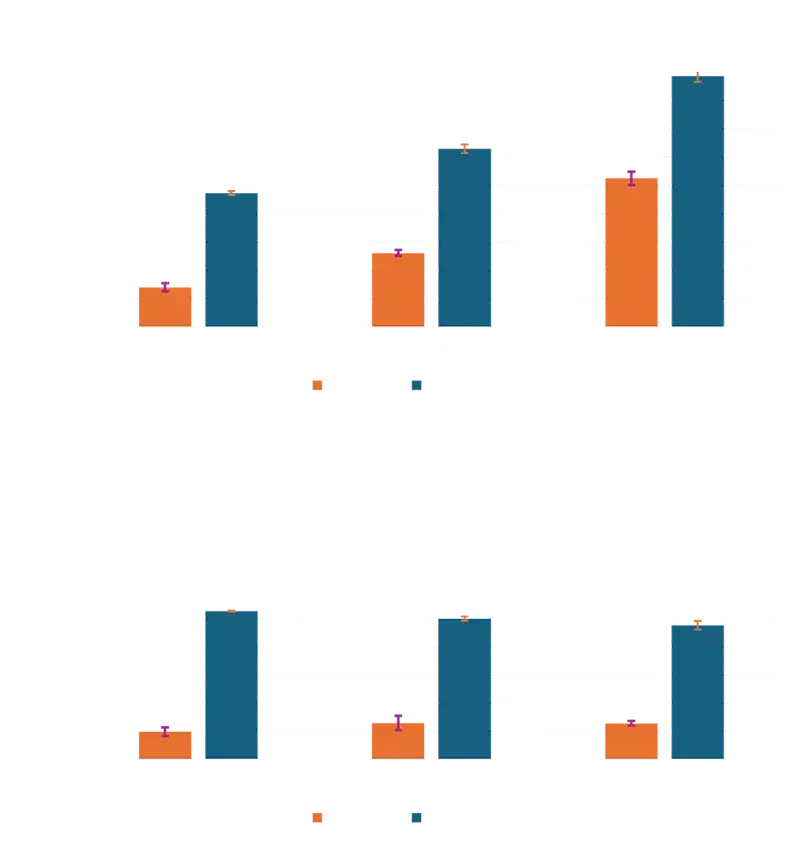

Synthetic air or medical-grade air has historically been used as the combustion gas for the cetane analyzer. Each time you change a gas bottle with these, the percentage of oxygen in the gas bottles varies due to batch variations. These differences can be +/-0.5% of the oxygen content. This is enough to impact the measurement, and thus calibration needs to be performed on the CID after every gas change. With ZyNthAir, the oxygen content is always within +/-0.05% of the desired combustion gas, even after changing gas cylinders.

That’s why using ZyNthAir with the CID takes this performance to the next level. Controlling the oxygen content in the combustion gas to high levels of precision means that results are more accurate across the full span of cetane measurements, allowing you to run closer to specification and ultimately save on giveaway.

Reduce the cost of Ownership

The cost of synthetic air and the routine expense of calibrating the cetane analyzer after each gas change can accumulate significantly over time.

For example, if the cost of synthetic air is $300 and zero air is $50 for a 200-bar, 50-liter cylinder, and if we have one bottle connected to the cetane analyzer and perform a calibration after every gas change, the total cost of running the system without ZyNthAir compared to running it with ZyNthAir is $18.5K per year. Talk to PAC today about how much you could save!

Reducing the need to perform calibrations simplifies the workload and complexity of operating the system, and it also reduces the uncertainty about whether the calibration was performed correctly. Additionally, reducing the need for certified reference materials (CRM) and validation materials after every gas change has a positive environmental impact. All this is achieved while maintaining backward compatibility with the existing CID 510 analyzer by PAC.

Why the ZyNthAir

Reduces operation cost for routine Cetane calibrations

No need to run calibrations or CRMs after gas cylinder changes, and no more expensive synthetic air. Reducing the need for frequent calibration helps optimize your scheduling while simplifying the use of the instrument.

Optimizes the performance of PAC CID Cetane analyzers

Synthetic air, with oxygen content variations of +/-0.5%, has been used for combustion. ZyNthAir, however, maintains oxygen content within +/-0.05%, ensuring consistent combustion gas composition and eliminating the need for frequent calibrations. This high precision improves accuracy across cetane measurements, allowing for closer adherence to specifications and reducing costs.

Removes the need to have multiple gas bottle racks

ZyNthAir eliminates the need for multiple gas bottle racks, simplifying the setup and operation of the cetane analyzer and saving valuable space. Gas bundles can experience changes in oxygen content as cylinder volume decreases, affecting calibration accuracy. ZyNthAir ensures consistent oxygen levels, streamlining the process of changing bottles and calibrating the system. This leads to a more efficient and less cumbersome operation.

Backward Capability with existing Cetane analyzers

With existing CID analyzers from PAC simply connect the output combustion air line from the ZyNthAir and you are ready to enjoy the benefits.

Get the Brochure

Learn how the ZyNthAir can help you produce unparalleled accuracy in oxygen content, giving your CID510 analyzer reliable combustion gas to power better Cetane measurement.

Get the Brochure